What is an air compressor?

An air compressor is a machine designed to produce compressed air. The compressed air becomes a source of energy for pneumatic accessories and tools, such as, blowers, paint guns, jackhammers, etc.

How they work

The air is sucked into a cylinder on the piston-down stroke and then compressed and fed to the tank on the same piston’s up stroke (exactly the same principle as a bicycle pump).

How is a compressor’s performance measured?

ITwo parameters need to be taken into account: pressure and flow rate.

The pressure is measured in bar (1 bar = 1 kg / cm2).

The flow rate is measured in litres per minute or m3 per hour.

A distinction must be made between the suction flow rate (volume of air sucked in by the compressor) and the discharge flow rate (volume of compressed air produced by the compressor) – the latter should be used when choosing a compressor.

The pressure and flow rate are needed to determine the most appropriate compressor.

Direct drive or belt drive compressors?

The cylinder or cylinders are driven by a direct coupling to an electric motor (direct drive), or via a belt.

How to decide which compressor to buy ?

You need to determine:

1/ The intended use: blow, inflate, paint, tighten, etc,

2/ The usage intensity: occasional, regular or intensive,

3/ Usage frequency: intermittent or continuous,

As a general rule, you should choose an air compressor with a discharge air flow rate that is equal to or slightly higher than the consumption of the tool or accessory that will be used.

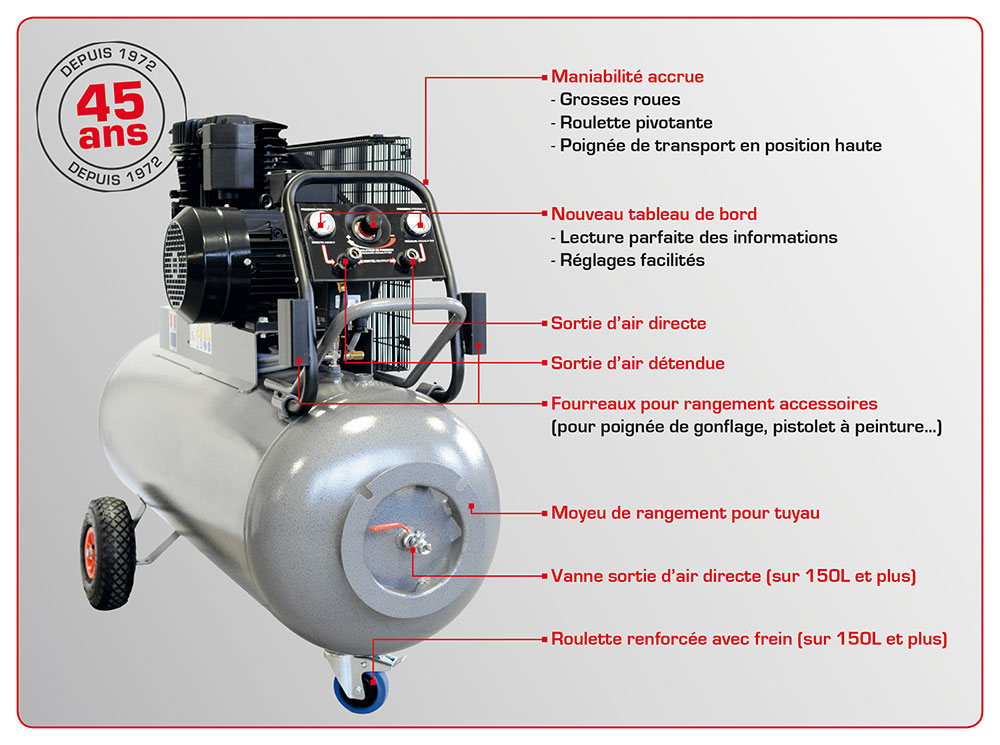

What are the advantages of the TRE range?